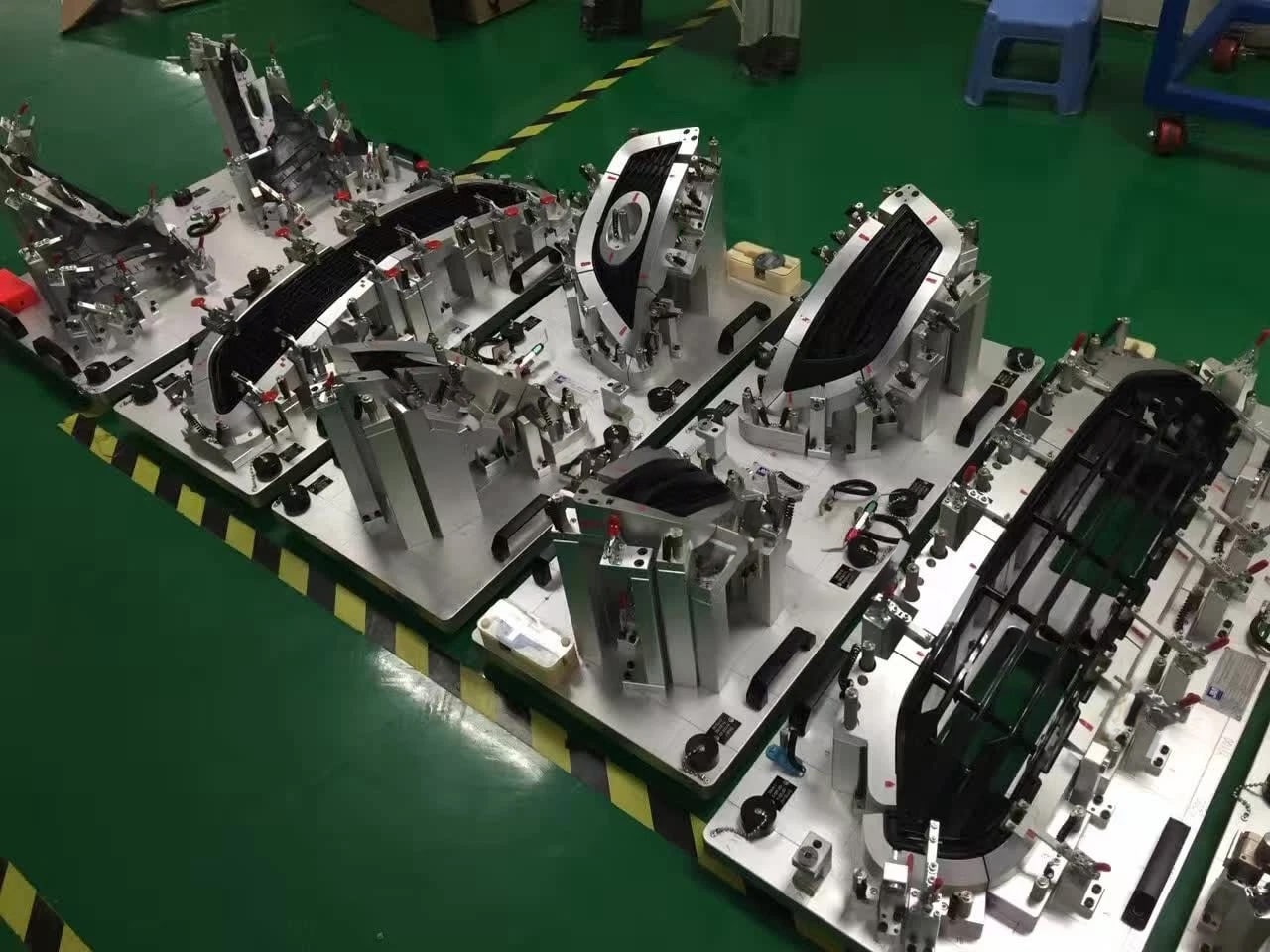

Checking fixture design is crucial for ensuring that parts meet specified dimensions and tolerances consistently during the manufacturing process. Checking fixtures, also known as inspection fixtures, are used to measure, verify, and validate the dimensions and geometry of parts.

The fixture must be designed to hold parts with high accuracy, ensuring that measurements are reliable.

The design should ensure that parts are inspected consistently and repeatedly with the same results.

By focusing on these aspects, checking fixture design can significantly enhance the quality and efficiency of the manufacturing inspection process.

Benefits

Understand the critical dimensions and features that need to be inspected.

Improved Quality Control

Increased Efficiency

Consistency and Repeatability

Enhanced Data Collection

What are the fundamental purposes of checking fixtures in manufacturing?

- Checking fixtures are used to verify the dimensions, geometry, and positional accuracy of parts to ensure they meet design specifications and tolerances. They provide a controlled environment for measurement and inspection, contributing to consistent quality and reducing defects.

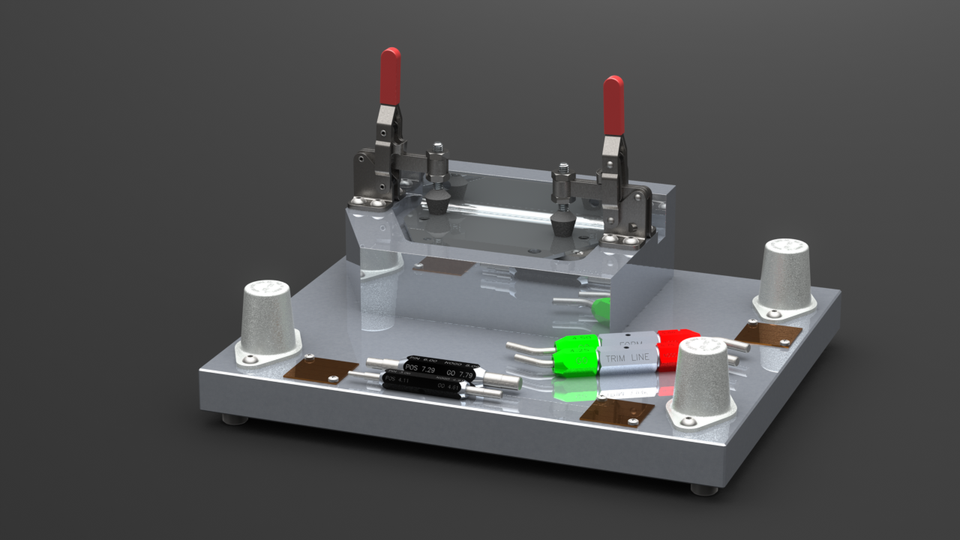

What are the primary components of a checking fixture?

- The primary components of a checking fixture include:

- Locators: Ensure the part is positioned accurately.

- Gauging Points: Specific locations where measurements are taken.

- Clamps: Hold the part securely during inspection.

- Bases: Provide a stable platform for the fixture.

- Probes and Sensors: Used for taking contact or non-contact measurements.

How does a checking fixture enhance quality control in the manufacturing process?

- By providing precise and repeatable positioning of parts, checking fixtures allow for accurate measurements and inspections. This reduces variability, identifies non-conforming parts, and minimizes the risk of defects reaching subsequent stages of production or the customer.

How can the design of a checking fixture improve ergonomics for operators?

- The design can improve ergonomics by:

- Ease of Loading/Unloading: Simplifying the process of placing and removing parts.

- Operator Accessibility: Ensuring that all components are within easy reach.

- Reducing Strain: Minimizing the physical effort required to use the fixture, thus reducing operator fatigue and the risk of injury.