Press tool design is a specialized field within mechanical engineering focused on designing tools and dies used in manufacturing processes such as stamping, punching, blanking, and forming. These tools are critical in mass production industries for creating parts and components from sheet metal or other materials.

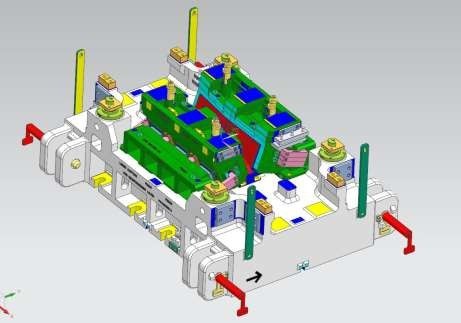

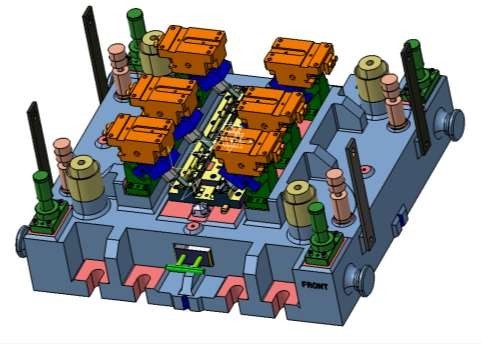

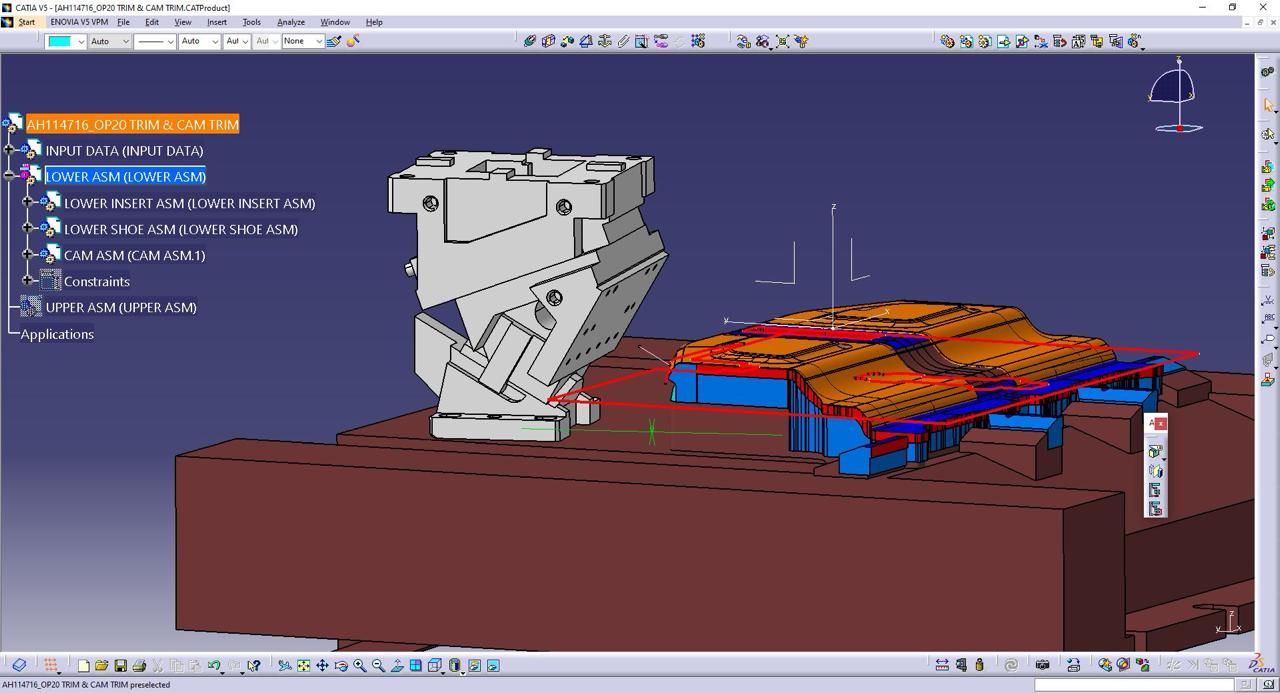

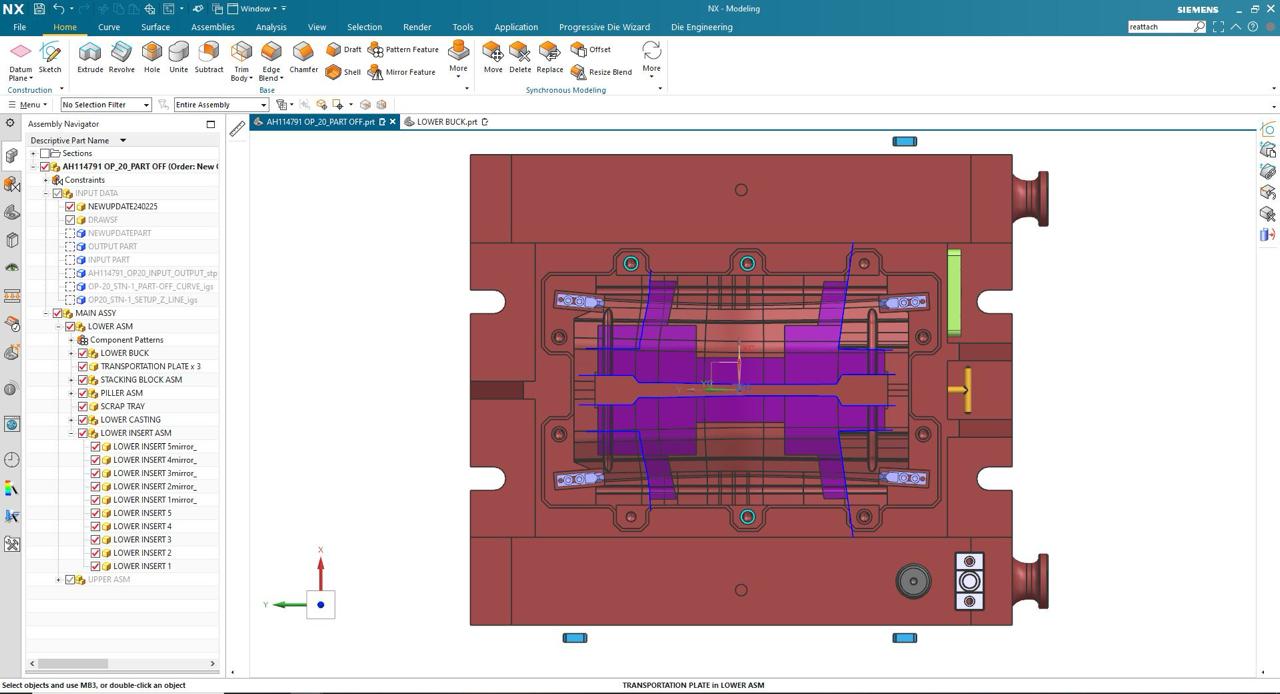

Designing various tools such a draw tool, forming tool, trimming tool, cam operated tools.

Using computer-aided design (CAD) software and simulation tools to analyze the performance of the press parts under different conditions, ensuring it meets quality and production requirements.

Benefits:

A perfect Press Tool Design not only reduces manufacturing lead time but also enhances product quality.

We assure:-

We assure:-

Optimized tool size

Cost Reduction

Standards as per requirement

Minimal Lead Time

Softwares Used

We have latest and licensed software for designing the marvel which can outstand the ultra.

UGNX 12

Catia V5

What are the primary considerations in press tool design?

- Material: Ensure the tool material is strong enough to withstand the forces and wear.

- Tool life: Design for durability and ease of maintenance.

- Precision: Accuracy in dimensions and alignment.

- Cost: Balance between initial investment and long-term savings.

- Production volume: Optimize for the expected quantity of parts to be produced.

What are the main types of press tools?

- Blanking Tools: Used for cutting out a flat shape from a sheet metal.

- Piercing Tools: Create holes or cutouts in sheet metal.

- Forming Tools: Bend, fold, or shape sheet metal into desired forms.

- Drawing Tools: Used to form sheet metal into cup-shaped or box-shaped components.

What are the key design considerations for minimizing production costs?

- Material Usage: Minimize scrap and waste material.

- Cycle Time: Optimize the design for faster production cycles.

- Tool Maintenance: Design for easy maintenance and repair.

- Automation: Integrate automation where feasible to reduce labor costs.

- Tool Longevity: Ensure the tool is durable to avoid frequent replacements.

How does press tool design affect part quality?

- Accuracy: Ensures parts meet dimensional specifications.

- Surface Finish: Smooth finish without defects.

- Consistency: Produces parts with uniform quality.

- Tolerance Control: Maintains tight tolerances as required by design.

- Repeatability: Consistent performance over many production cycles.